It’s common to have some discrepancies with items when taking inventory. We have listed some basic troubleshooting steps below, when an inventory discrepancy occurs at item level:

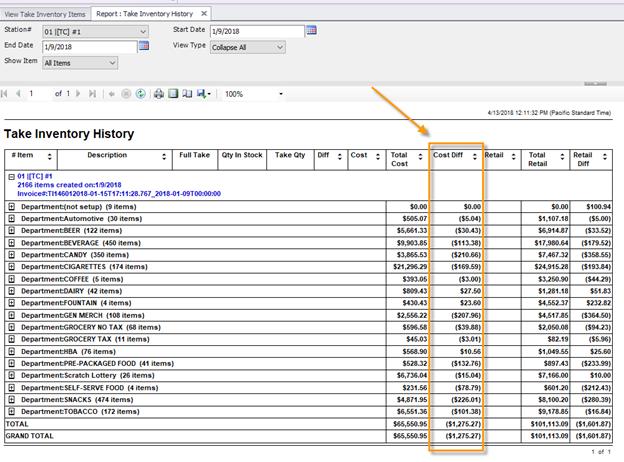

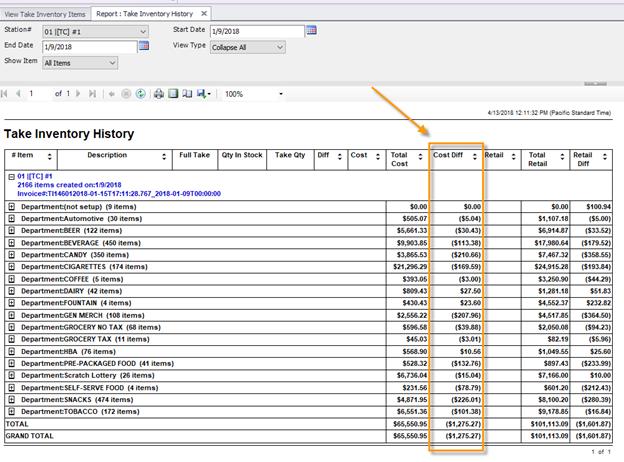

1. Open the Take Inventory invoice and first determine which dept(s) are having an issue.

2. Then, expand the dept and identify which items are causing the discrepancy- and note the sku number(s)

3. Then, open the Inventory History module to research

Search for the UPC & station

This will open the history of the item to research and determine issue

Possible causes of issues:

• Are you missing sales for an item?

• Are you missing purchases for an item?

• Do you purchase one sku, but sell under another sku and the 2 need to be assembled/linked?

• Was the last audit count correct?

• Are the items being counted in the same way/pack size they were received in?

• Is there a trend of items that appear to be continually missing? Potential for theft.

An inventory grand total has a lot to factor-in. If you're only looking at that number, and you're not breaking down to areas contributing to that value then you are going to continually see a large variance from inventory count to another.

If you have an O/S problem then you need to utilize the information you have collected to find out why.

Only then will you know what needs to be fixed.